目录

电机型号

步进电机:图解: 步进电机原理与驱动方式 - 知乎 (zhihu.com)

驱动方式

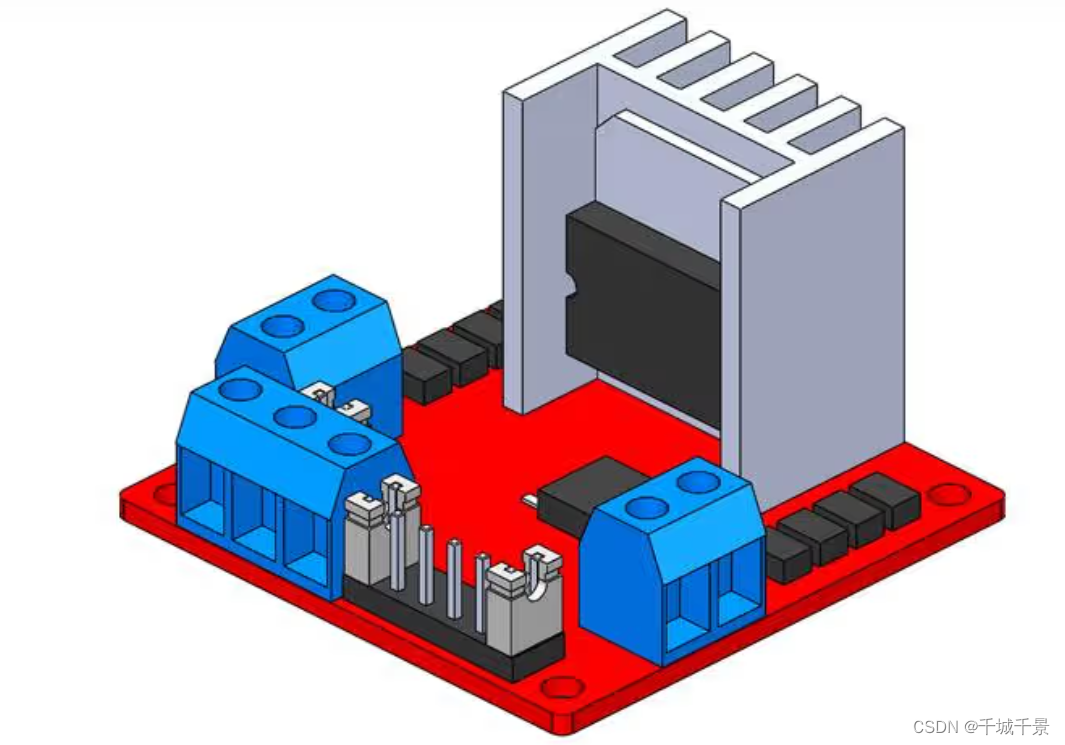

L298N:L298N 电机驱动板 - 详细介绍 - 知乎 (zhihu.com)

工作方式

PWM驱动,控制电机运动的速度、力矩

代码

drive.c

参考官方的代码,输出程序:drive.c

#include <drive.h>

/*

* 函数:PWM_Init()

* 功能:初始化PWM

* P1.2

* P1.3

*/

void PWM_Init(void)

{

//TA0CTL = 0; //清除以前的设置

//TA0CTL = MC_1; //定时器TA选择为增记数模式

TA0CTL |= ID_0; //设置分频系数

/*设置PWM通道一P1.2的输出模式*/

//TA0CCTL1 = OUTMOD_7; //高电平PWM输出,占空比设置的是高电平的占空比

TA0CCTL1 = OUTMOD_3; //低电平PWM输出,占空比设置的是低电平的占空比

P1DIR |= BIT2; //P1.2为输出

P1SEL |= BIT2; //P1.2为输出

/*设置PWM通道二P1.3的输出模式*/

TA0CCTL2 = OUTMOD_7; //高电平PWM输出

P1DIR |= BIT3; //P1.3为输出

P1SEL |= BIT3; //P1.3为输出

TA0CTL = TASSEL_2 + MC_1;

}

/*

* 函数:TAPwmSetPermill(char Channel,unsigned int Percent)

* 功能:设置每一路的参数

* 入口参数:

* Channel:当前设置的通道数

* Percent:PWM有效时间的千分比(0~1000)

*/

void TAPwmSetPermill(char Channel,unsigned int Percent)

{

unsigned long int Period;

unsigned int Duty;

Period = TA0CCR0;

Duty = Period * Percent /1000;

switch(Channel)

{

case 1:

TA0CCR1 = Duty;

break;

case 2:

TA0CCR2 = Duty;

break;

case 3:

TA0CCR3 = Duty;

break;

case 4:

TA0CCR4 = Duty;

break;

}

}

drive.h

#ifndef __DRIVE_H

#define __DRIVE_H

#include <msp430.h>

#include <stdio.h>

void PWM_Init(void);

void TAPwmSetPermill(char Channel,unsigned int Percent);

#endif

main.c

/*

* 通道1:P1.2

* 通道2:P1.3

* 通道1输出PWM信号,200HZ,20%占空比

*/

#include <msp430.h>

#include <drive.h>

int main(void)

{

WDTCTL = WDTPW | WDTHOLD; // stop watchdog timer

PWM_Init();

TA0CCR0 = 5000;

TAPwmSetPermill(1,400); //1通道,40%的占空比

TAPwmSetPermill(2,500); //2通道,50%的占空比

while(1);

}

(后面好像使用的时候会有什么冲突导致1或者2通道无法正常运行,不太记得了,可以到实物上实验一下子)

智能送药小车

下面是部分智能送药小车使用PWM驱动电机相关代码与注释

car.h

#ifndef __CAR_H

#define __CAR_H

#include <msp430.h>

void CAR_PWM_Init(void);

void CAR_RUN_Init(void);

void Capture_Init(void);

void CAR_Init(void);

void TAPwmSetPermill(char Channel,unsigned int Percent);

#endif

car.c

#include <car.h>

/*******************************

* PWM初始化

* 前轮: 左——P1.2 右——P1.3

* 后轮: 左——P1.4 右——P1.5

*******************************/

void CAR_PWM_Init()

{

TA0CTL |= ID_0;

P1DIR |= BIT2 + BIT3 + BIT4 + BIT5;

P1SEL |= BIT2 + BIT3 + BIT4 + BIT5;

TA0CCTL1 = OUTMOD_7;

TA0CCTL2 = OUTMOD_7;

TA0CCTL3 = OUTMOD_7;

TA0CCTL4 = OUTMOD_7;

TA0CTL = TASSEL_2 + MC_1 + TACLR;

TA0CCR0 = 1000;

}

/*

* 电机控制端GPIO设置

* AIN1 AIN2

* 左前 P6.0 P6.1

* 右前 P6.2 P6.3

* 左后 P6.4 P7.0

* 右后 P6.5 P6.6

*/

void CAR_RUN_Init(void)

{

P6DIR |= BIT0 + BIT1 + BIT2 + BIT3 + BIT4 + BIT5 + BIT6;

P6OUT &= ~(BIT0 + BIT1 + BIT2 + BIT3 + BIT4 + BIT5 + BIT6);

P7DIR |= BIT0;

P7OUT &= ~BIT0;

}

/***************************

* 输入捕获:

* 前轮: 左——P2.0 右——P2.1

* 后轮: 左——P2.2 右——P3.6

***************************/

//IO口存在冲突,待改进,改为两个PWM以及两个输入捕获端口,解决定时器不足问题

/*void Capture_Init(void)

{

P2DIR &= ~(BIT4 + BIT5);

P2SEL |= BIT4 + BIT5;

TA2CTL = MC_2 + TASSEL_2 + ID_0 + TACLR;

TA2CCTL1 = CM_1 + SCS + CAP + CCIE + CCIS_0;

TA2CCTL2 = CM_1 + SCS + CAP + CCIE + CCIS_0;

P3DIR &= ~(BIT5 + BIT6);

P3SEL |= BIT5 + BIT6;

TB0CTL = MC_2 + TASSEL_2 + ID_0 + TACLR;

TB0CCTL1 = CM_1 + SCS + CAP + CCIE + CCIS_0;

TB0CCTL2 = CM_1 + SCS + CAP + CCIE + CCIS_0;

}*/

void CAR_Init(void)//初始化

{

CAR_PWM_Init();

CAR_RUN_Init();

//Capture_Init();

}

void TAPwmSetPermill(char Channel,unsigned int Percent)//选择通道,设置该通道输出的占空比,改变小车速度

{

unsigned long int Period;

unsigned int Duty;

Period = TA0CCR0;

Duty = Period * Percent /1000;

switch(Channel)

{

case 1:

TA0CCR1 = Duty;

break;

case 2:

TA0CCR2 = Duty;

break;

case 3:

TA0CCR3 = Duty;

break;

case 4:

TA0CCR4 = Duty;

break;

}

}

main.c

/*

* 第四个版本

* 红外循迹四轮小车,旋转式转向,可前进与倒退

*

* 下一个版本改进计划:

* 小车改为两个PWM驱动

* 添加输入捕获,更新为闭环控制

* 添加PID算法,运动控制更稳定

* 修改定时器工作方式,精确计算时间,计算行驶路程

* 添加OLED,实时显示参数

*/

#include <msp430.h>

#include <car.h>

#include <redled.h>

void delay(int ms);

void RED_LED_Flag(void);

void CAR_F_R(int mode_1);

void CAR_R_F(unsigned int a,unsigned int b,unsigned int c,unsigned int d);

void CAR_TEXT(void);

int main(void)

{

WDTCTL = WDTPW | WDTHOLD;

//RED_LED_Init();//开启红外功能,初始化

CAR_Init();

while(1)

{

//RED_LED_Flag();//开启小车全部功能

CAR_TEXT();//测试小车功能

}

}

void CAR_TEXT(void)

{

CAR_R_F(200,200,200,200);

CAR_F_R(0);

}

//延时函数——伪

void delay(int ms)

{

int i,j;

for( i = 0; i < ms; i ++)

{

for( j = 0; j < 240; j ++);

}

}

void RED_LED_Flag(void) //小车功能实现

{

if( (P4IN & BIT1) != 0 && (P4IN & BIT2) != 0)//都识别到黑线

{

CAR_F_R(4); //停止

CAR_R_F(000,000,000,000);

}

if( (P4IN & BIT1) == 0 && (P4IN & BIT2) == 0)//都未识别到黑线

{

CAR_F_R(0); //前进

CAR_R_F(200,200,200,200);

}

if( (P4IN & BIT1) != 0 && (P4IN & BIT2) == 0)//左识别到黑线,左转

{

CAR_F_R(6); //旋转左转

CAR_R_F(300,300,300,300);

}

if( (P4IN & BIT1) == 0 && (P4IN & BIT2) != 0)//右识别到黑线,右转

{

CAR_F_R(5); //旋转右转

CAR_R_F(300,300,300,300);

}

}

void CAR_F_R(int mode_1)//控制前后行动,控制IN1,IN2

{

switch(mode_1)

{

case 0://前行

P6OUT &= ~(BIT0 + BIT2 + BIT4 + BIT5); //0

P6OUT |= BIT1 + BIT3 + BIT6; //1

P7OUT |= BIT0;

break;

case 1://后退

P6OUT |= BIT0 + BIT2 + BIT4 + BIT5; //1

P6OUT &= ~(BIT1 + BIT3 + BIT6); //0

P7OUT &= ~BIT0; //0

break;

case 2://左转

P6OUT &= ~BIT0; //0,P6.0

P6OUT &= ~BIT1; //0

P6OUT &= ~BIT2; //0,P6.2

P6OUT |= BIT3; //1

P6OUT &= ~BIT4; //0,P6.4

P7OUT &= ~BIT0; //0

P6OUT &= ~BIT5; //0

P6OUT |= BIT6; //1

break;

case 3://右转

P6OUT &= ~BIT0; //0

P6OUT |= BIT1; //1

P6OUT &= ~BIT2; //0

P6OUT &= ~BIT3; //0

P6OUT &= ~BIT4; //0

P7OUT |= BIT0; //1

P6OUT &= ~BIT5; //0

P6OUT &= ~BIT6; //0

break;

case 4://停止

P6OUT &= ~(BIT0 + BIT1 + BIT2 + BIT3 + BIT4 + BIT5 + BIT6); //0

P7OUT &= ~BIT0;

break;

case 5://左旋转

P6OUT &= ~BIT0; //0

P6OUT |= BIT1; //1

P6OUT |= BIT2; //1

P6OUT &= ~BIT3; //0

P6OUT &= ~BIT4; //0

P7OUT |= BIT0; //1

P6OUT |= BIT5; //1

P6OUT &= ~BIT6; //0

break;

case 6://右旋转

P6OUT |= BIT0; //1

P6OUT &= ~BIT1; //0

P6OUT &= ~BIT2; //0

P6OUT |= BIT3; //1

P6OUT |= BIT4; //1

P7OUT &= ~BIT0; //0

P6OUT &= ~BIT5; //0

P6OUT |= BIT6; //1

break;

default:

break;

}

}

void CAR_R_F(unsigned int a,unsigned int b,unsigned int c,unsigned int d)//控制速度

{

TAPwmSetPermill(1,a);

TAPwmSetPermill(2,b);

TAPwmSetPermill(3,c);

TAPwmSetPermill(4,d);

}